.png?width=1600&height=900&name=Hero%20image%20(6).png)

Recursos

Explora nuestros recursos para acceder a información experta en el campo de life sciences. Aquí encontrarás una amplia variedad de contenido, que incluye informes técnicos detallados, artículos de blog, casos de estudios, webinars y actualizaciones normativas.

Ya sea que trabajas en Pharma, Biotech, Medical Devices o cualquier otro sector, nuestros diversos servicios y la orientación de nuestros expertos están diseñados para mantenerte informado y a la última de las tendencias del sector. Descubre nuestro contenido y mantente al día con los avances más recientes y las prácticas más óptimas.

Ya sea que trabajas en Pharma, Biotech, Medical Devices o cualquier otro sector, nuestros diversos servicios y la orientación de nuestros expertos están diseñados para mantenerte informado y a la última de las tendencias del sector. Descubre nuestro contenido y mantente al día con los avances más recientes y las prácticas más óptimas.

All

Blog

Case study

Regulatory update

Webinar

Whitepaper

All Industry

In Vitro Diagnostics

Medical Devices

Pharma & Biotech

All Service

Quality Assurance

Clinical

Lab Services

Qualification & Validation

Vigilance

Regulatory Affairs

Software Solutions & Services

Toxicology

Filter

All

Blog

Case study

Regulatory update

Webinar

Whitepaper

All industries

In Vitro Diagnostics

Medical Devices

Pharma & Biotech

All services

Quality Assurance

Clinical

Lab Services

Qualification & Validation

Vigilance

Regulatory Affairs

Software Solutions & Services

Toxicology

Whitepaper

16 sep 2024

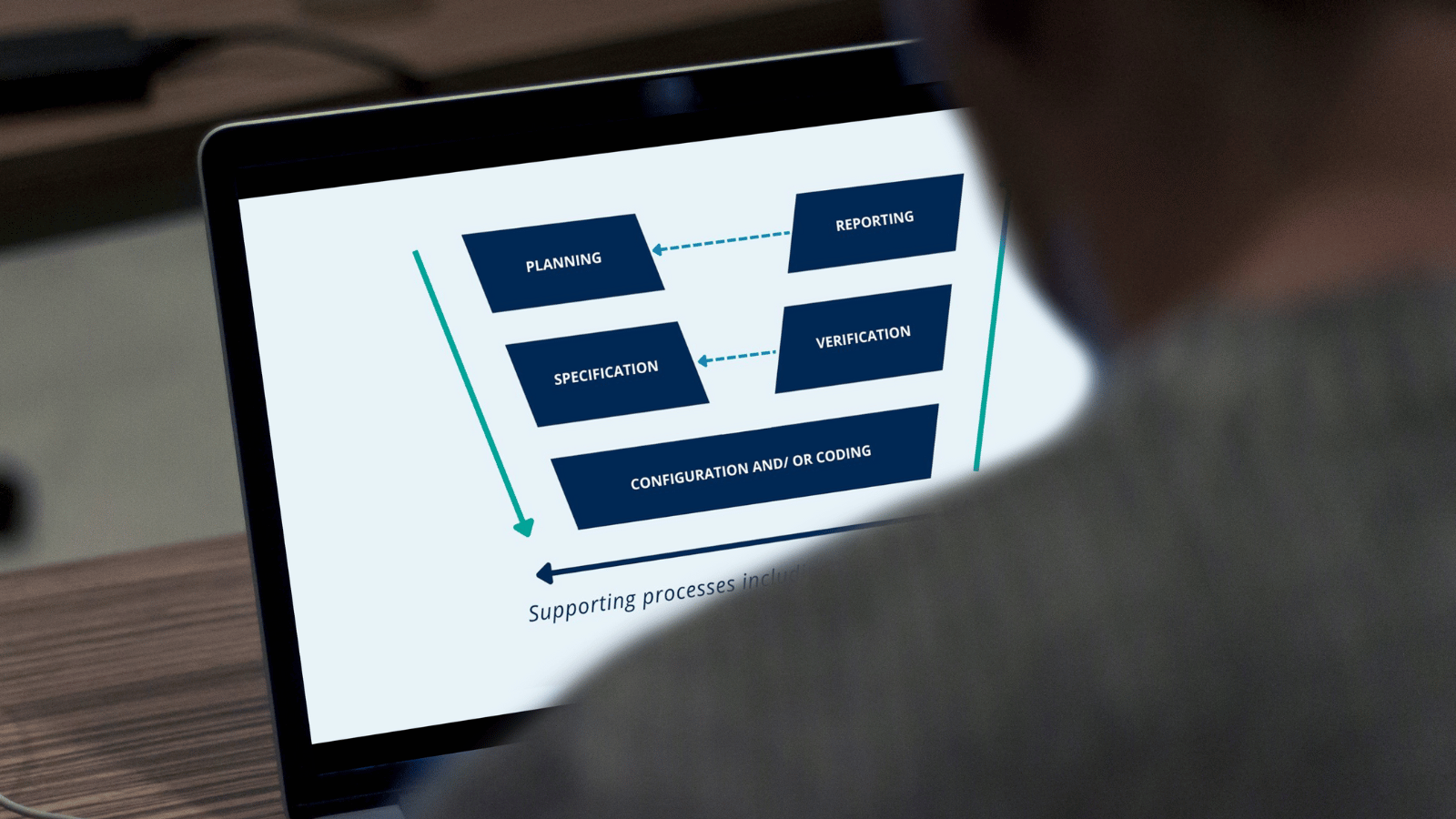

Del modelo V al Agile: cómo adoptar la automatización en la validación de sistemas computarizados

Este whitepaper explora el cambio hacia Agile en IT, con un enfoque en la metodología Scrum y concluye con orientación sobre cómo adaptar los procesos de validación de sistemas.

Leer más

Whitepaper

23 dic 2024

Revisión bibliográfica de última generación: inicia la evaluación clínica de tu dispositivo médico

Este whitepaper te guiará paso a paso en la realización de búsquedas bibliográficas sistemáticas sólidas para la evaluación clínica de tu dispositivo médico. Descárgalo ahora.

Leer más

Whitepaper

8 oct 2024

El papel clave de Asuntos Regulatorios en la industria farmacéutica: desde el desarrollo hasta la comercialización

Descubre el papel clave de los Asuntos Regulatorios en la industria farmacéutica y cómo los equipos de Regulatory Affairs apoyan la gestión del ciclo de vida del producto.

Leer más

Case study

25 mar 2024

Garantizar una transición fluida de los productos sanitarios de Oystershell al MDR

El panorama de las normativas sobre productos sanitarios evoluciona constantemente, lo que supone un reto para las empresas mantenerse al día. Nuestra colaboración con Oystershell, que comenzó en...

Leer más

.png)

Case study

31 may 2024

Garantizar la calidad de la producción farmacéutica: validación de la limpieza para una agencia gubernamental

Descubra cómo QbD Group ayudó a un cliente a afrontar los retos de la doble validación de sus líneas de producción, garantizando el cumplimiento de las GMP y la aprobación de la AEMPS.

Leer más

Case study

27 jun 2024

Garantizar el lanzamiento a tiempo: El papel del Grupo QbD en la creación de una línea de producción de medicamentos para la hemofilia

QbD Group ha facilitado la puesta en marcha de una nueva línea de producción de fármacos para el tratamiento de la hemofilia, supervisando la cualificación de más de 100 equipos de apoyo a pequeña...

Leer más

Case study

30 oct 2024

Guiar la investigación del glioblastoma de la Universidad Católica de Lovaina hacia la clínica con una planificación empresarial precisa

Ayudamos a la Universidad Católica de Lovaina a trasladar la investigación sobre el glioblastoma a la clínica con planificación empresarial estratégica, apoyo financiero y una hoja de ruta para el...

Leer más

Case study

28 jun 2024

Optimización de la farmacovigilancia para una empresa líder en biotecnología

Ayudamos a la Universidad Católica de Lovaina a trasladar la investigación sobre el glioblastoma a la clínica con planificación empresarial estratégica, apoyo financiero y una hoja de ruta para el...

Leer más

Case study

31 may 2024

Revolucionando la farmacovigilancia: una historia de éxito de asociación estratégica e integración sin fisuras

Descubra cómo el apoyo experto de QbD Group mejoró la farmacovigilancia de una empresa farmacéutica, lo que condujo a un resultado de inspección favorable por parte de la Autoridad Reguladora local...

Leer más

Webinar

On-demand

9 ene 2025

Evidencia a lo largo del ciclo de vida: integrando necesidades clínicas en diseño y documentación

Aprende cómo integrar las necesidades clínicas en el diseño de software para dispositivos médicos y cumplir con los requisitos de MDR. Visualiza ahora nuestro webinar bajo demanda.

Leer más

Webinar

On-demand

6 ene 2025

De los requisitos al código: un ciclo de desarrollo unificado para software de dispositivos médicos

Aprende sobre el desarrollo de software para dispositivos médicos, incluidos los estándares IEC, ciberseguridad, integración de IA y expectativas de la FDA en este webinar.

Leer más

Webinar

On-demand

24 dic 2024

Del concepto al mercado: estrategias integrales de acceso al mercado para software de dispositivos médicos

Descubre cómo lanzar con éxito el software para dispositivos médicos, con conocimientos clave sobre estrategias de acceso al mercado y comercialización. Visualiza ahora nuestro webinar.

Leer más

.jpg)

Webinar

On-demand

19 nov 2024

Primeros pasos: superando obstáculos iniciales en el desarrollo de software para dispositivos médicos

Supera los obstáculos iniciales en el desarrollo de software para dispositivos médicos y en el cumplimiento con MDR, IA Act y mejores prácticas. Visualiza ahora nuestro webinar.

Leer más

.jpg)

Webinar

On-demand

8 dic 2024

Desbloqueando el valor estratégico en la seguridad de medicamentos para organizaciones de ciencias de la vida

Descubre cómo los equipos de seguridad farmacológica pueden transformarse en impulsores proactivos de beneficios con las herramientas y recursos adecuados en este webinar bajo demanda.

Leer más

Webinar

On-demand

13 feb 2025

Bases de datos de seguridad en Farmacovigilancia: ¿Cuál es su importancia estratégica?

13 de febrero | 16:00 CET |Descubre la importancia de las bases de datos de seguridad en farmacovigilancia y mejora tu gestión de eventos adversos en nuestro próximo webinar. ¡Regístrate ahora!

Leer más

Webinar

On-demand

20 feb 2025

El uso de la IA en Farmacovigilancia: gestión de ICSRs y otras aplicaciones clave

20 de febrero | 16:00 CET | Descubre en nuestro próximo webinar cómo la IA transforma la farmacovigilancia, optimizando la detección de eventos adversos y mejorando la seguridad del paciente....

Leer más

Webinar

On-demand

27 feb 2025

Transformando consultas en insights: el rol estratégico de los Medical Call Centers en Pharma

27 de febrero | 16:00 CET | Descubre cómo los Medical Call Centers transforman consultas en insights estratégicos en la industria farmacéutica en nuestro próximo webinar. Regístrate ahora y aprende...

Leer más

Case study

1 abr 2025

Una década de excelencia: soporte en revisión lingüística para un líder farmacéutico global.

QbD Group optimiza las revisiones lingüísticas para un cliente farmacéutico líder, garantizando cumplimiento y precisión en 25 idiomas de la UE/EEE, cumpliendo con estrictos plazos regulatorios.

Leer más

Webinar

On-demand

13 may 2025

De la evaluación al cumplimiento: guía práctica sobre el riesgo de las nitrosaminas

Descubre cómo gestionar el riesgo de las nitrosaminas en la industria farmacéutica en nuestro webinar. Inscríbete y aprende de la mano de expertos todo sobre regulaciones y el análisis de riesgo.

Leer más

Case study

28 may 2025

Validación de una carga de autoclave compleja para optimizar la eficiencia de la esterilización

Descubre cómo QbD Group ayudó a una planta farmacéutica de Barcelona a optimizar y validar una compleja carga de autoclave, mejorando la eficacia de la esterilización y la flexibilidad de la...

Leer más

Blog

27 jun 2025

La farmacovigilancia es una responsabilidad compartida: Por qué la notificación de eventos adversos es más importante que nunca

Descubre cómo los profesionales sanitarios y los pacientes contribuyen a la seguridad de los medicamentos informando sobre acontecimientos adversos: una parte...

Leer más

Blog

27 may 2025

El papel de las Buenas Prácticas de Distribución (GDP) y de la Gestión del Riesgo de Calidad (QRM) para garantizar la integridad farmacéutica

Descubre cómo las Buenas Prácticas de Distribución (GDP) y la Gestión de Riesgos de Calidad (QRM) garantizan la integridad, seguridad y cumplimiento de los...

Leer más

Blog

7 may 2025

Una planificación y gestión más inteligente de las auditorías en life sciences: cumplir la normativa y ahorrar tiempo

Mejora la planificación, ejecución y seguimiento de auditorías en life sciences con un enfoque estructurado y basado en el riesgo — además de cuándo y por qué...

Leer más

Blog

25 abr 2025

La importancia de las auditorías de farmacovigilancia veterinaria: Protegiendo la salud global cumpliendo con las normativas vigentes

Las auditorías de farmacovigilancia veterinaria son fundamentales para la salud global. Descubre cómo QbD te ayuda a cumplir con las VGVP y garantizar la...

Leer más

Blog

5 mar 2025

Container Closure Integrity Testing (CCIT) en la Industria Farmacéutica: Garantizando la seguridad de los envases farmacéuticos.

Aprende cómo las Container Closure Integrity Testing (CCIT) en la Industria Farmacéutica protegenlos envases farmacéuticos, garantizando la esterilidad,...

Leer más

Blog

13 feb 2025

Revisión del anexo 1 de las GMP de la UE: Fabricación de medicamentos estériles - Resumen y primeras impresiones

En 2022 se revisó el Anexo 1 de las GMP de la UE, Fabricación de medicamentos estériles. En esta entrada del blog, proporcionaremos un resumen de los cambios y...

Leer más

Blog

25 sep 2024

Mantener la excelencia en la validación: Mejora continua mediante revisiones periódicas de la validación en la Industria Farmacéutica

Aprende cómo las revisiones periódicas de validación mantienen la conformidad del sistema farmacéutico, utilizando el análisis basado en el riesgo y la...

Leer más

Blog

18 sep 2024

La Tecnovigilancia en acción: Protegiendo la salud con la vigilancia postcomercialización de los productos sanitarios

Descubre cómo la tecnovigilancia garantiza la seguridad de los dispositivos médicos a través de la vigilancia post-comercialización, abordando los principales...

Leer más

Blog

16 sep 2024

Externalización de los procesos de conocimiento en la seguridad de los medicamentos: Una externalización más inteligente para una asistencia sanitaria más segura

Descubre cómo la externalización estratégica de procesos de conocimiento (KPO) está revolucionando los departamentos de seguridad de los medicamentos...

Leer más

Blog

4 sep 2024

Dominio de la información sobre productos de la EU: el papel del proceso de revisión lingüística de la EMA en los procedimientos centralizados

Obtén información esencial sobre el proceso de revisión lingüística de la EMA de la información de producto de los medicamentos aprobados mediante el...

Leer más

Blog

19 abr 2024

Evaluaciones de riesgos medioambientales (ERA) en la industria farmacéutica: equilibrio entre salud y medio ambiente - QbD Group

Explore how Environmental Risk Assessment (ERA) helps ensure medicines heal us without harming the planet, balancing healthcare advances with ecological...

Leer más

Blog

5 dic 2023

Procedimiento de reconocimiento internacional de la MHRA tras el Brexit: navegando por el registro de medicamentos en el Reino Unido

Explora el nuevo Procedimiento de Reconocimiento Internacional (IRP) de la MHRA para medicamentos posteriores al Brexit y aprende a navegar por las...

Leer más

Blog

7 jul 2023

Diseño de cámaras climáticas o de estabilidad conforme a las GMP: la clave para garantizar la integridad del producto

En esta entrada del blog, nos adentramos en el mundo del diseño de cámaras climáticas que cumple con las GMP y desentraña el papel vital que desempeñan en las...

Leer más

Blog

1 sep 2022

Colabora con una organización de investigación por contrato (CRO) dedicada a los productos sanitarios para impulsar tu estrategia de investigación clínica.

Descubre 5 razones para contratar a una Organización de Investigación por Contrato (CRO) especializada en estudios de productos sanitarios para apoyar tu...

Leer más

Blog

17 jul 2022

La importancia de las redes de distribución de alta calidad para los gases de proceso críticos, incluso en la fase inicial de desarrollo

La calidad de los gases de proceso y las redes de distribución de gas es cada vez más importante para los procesos farmacéuticos biotecnológicos y los sitios...

Leer más

Blog

25 abr 2021

De la idea a la vigilancia posterior a la comercialización: las fases del ciclo de vida de los productos sanitarios

El lanzamiento de un dispositivo médico requiere mucha preparación. Como estos dispositivos están fuertemente regulados, una empresa tiene que cumplir muchos...

Leer más

Regulatory update

1 jul 2025

Actualización de plazos de la FDA - Riesgo de impureza relacionada con sustancias activas de nitrosaminas (NDSRI)

El 23 de junio de 2025, la FDA publicó una aclaración sobre el próximo plazo del 1 de agosto de 2025 relacionado con las impurezas asociadas a sustancias...

Leer más

Regulatory update

6 mar 2025

Convocatoria de manifestaciones de interés para la evaluación coordinada de investigaciones clínicas/estudios de rendimiento

El 6 de febrero de 2025, los Estados Miembros de la UE y la Comisión Europea anunciaron el lanzamiento de una evaluación piloto coordinada de investigaciones...

Leer más

Regulatory update

18 sep 2024

La FDA publica una revisón de la guía sobre el control de las impurezas de nitrosaminas en medicamentos de uso humano

La FDA acaba de publicar una versión actualizada de su guía sobre el control de las impurezas de nitrosamina en los medicamentos de uso humano, que introduce...

Leer más

No Blog Post Found!

No Blog Post Found!

.png?width=109&height=108&name=Pharma%20(2).png)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)