.jpg?width=1280&height=720&name=Hero%20image%20(23).jpg)

Facility Qualification

What is facility qualification?

This process involves comprehensive testing and documentation to ensure these facilities are designed, constructed, and maintained to operate reliably and efficiently within the required standards.

Why is facility qualification important?

Facility qualification is more than a regulatory requirement; it is essential for ensuring operational integrity and product quality. Here's why it matters:

-

Regulatory compliance: Validating facilities and utilities ensures compliance with regulatory standards, safeguarding against disruptions to operations.

-

Enabling quality products: Validated facilities and utilities contribute to the production of high-quality products by providing the necessary infrastructure and environmental conditions.

-

Cost savings: It helps identify and mitigate risks associated with facility and utility failures, reducing the likelihood of downtime and safety incidents.

-

Operational efficiency: Ensuring the reliability and efficiency of facilities and utilities optimizes operational performance and reduces resource waste.

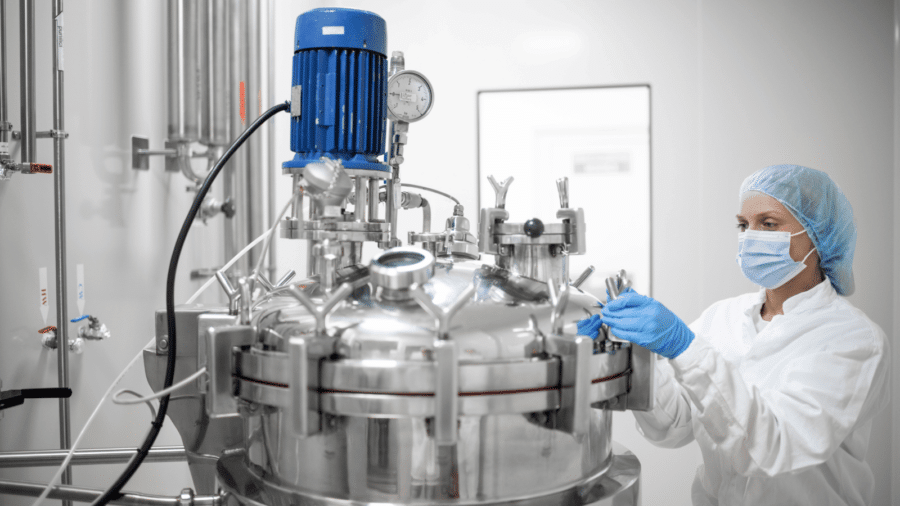

Cleanroom qualification

A cleanroom is a controlled environment where the concentration of airborne particles is managed and classified. It is designed, constructed, and operated in a way that effectively controls the introduction, generation, and retention of particles within the room. Additionally, other important parameters such as temperature, humidity, and pressure are controlled as required.

Cleanrooms are a critical component of pharmaceutical manufacturing, where even the smallest contamination can jeopardize product quality and safety. Whether you're producing sterile medications, biologics, or any other pharmaceutical products, maintaining a controlled, contaminant-free environment is paramount to ensure the integrity of your products.

At QbD Group, we specialize in providing comprehensive cleanroom qualification services designed to meet the highest standards of the pharmaceutical industry. With extensive expertise in cleanroom environments, our team ensures that your facilities operate at peak efficiency, safety, and compliance.

Our process

QbD Group provides flexible and scalable facility qualification services tailored to meet your project requirements. Whether you need a turnkey solution—where QbD manages the entire project from planning and execution to documentation—or a hybrid approach, where your company oversees project management while QbD handles the qualification process, we offer the expertise and adaptability to support your needs.

Step 1: Planning

We start with a detailed consultation to define project objectives, regulatory requirements, and timelines. A comprehensive qualification plan is developed to ensure expectations are clear and aligned.

Step 2: Execution

Our team conducts site assessments, testing, and inspections of facilities and utilities. We verify compliance with industry standards through rigorous testing and measurements.

Step 3: Documentation

All qualification activities are documented in detailed reports. These include protocols, testing results, and certifications to demonstrate compliance.

Step 4: Final review and validation

We review all findings, address any gaps, and finalize the qualification process. If needed, corrective actions are proposed to ensure facilities meet the required standards.

Why partner with QbD Group?

Facility qualification is a critical step in ensuring your facilities and utilities meet regulatory standards and operate efficiently. Our expert support during this phase helps you achieve compliance, reduce risks, and optimize performance, ultimately contributing to the production of high-quality products and significant cost savings.

-

During the C&Q portion of your project, clear and pragmatic project direction and execution are the first steps to a well-executed project.

-

Our expert support enables you to reduce the overall cost of your project.

-

Regulatory compliance: validating facilities and utilities ensures compliance with regulatory standards, safeguarding against disruptions to operations.

-

Enabling quality products: validated facilities and utilities contribute to the production of high-quality products by providing the necessary infrastructure and environmental conditions.

-

Cost savings: it helps identify and mitigate risks associated with facility and utility failures, reducing the likelihood of downtime and safety incidents.

-

Operational efficiency: ensuring the reliability and efficiency of facilities and utilities optimizes operational performance and reduces resource waste.

Get in touch

Ready to ensure your facilities and utilities meet the highest standards?

QbD Group provides expert facility qualification services to help you validate infrastructure, enhance performance, and ensure compliance. Contact us today to learn more.

.png?width=109&height=108&name=Pharma%20(2).png)

.png?width=111&height=108&name=Medical%20Devices%20(2).png)

.png?width=84&height=107&name=IVD%20(2).png)